Industrial Smart Glasses

With RealWear's industrial smart glasses, you can super power your workforce to get jobs done more accurately and efficiently than ever before, while improving the safety of your frontline workers by giving them the power of hands-free.

RealWear

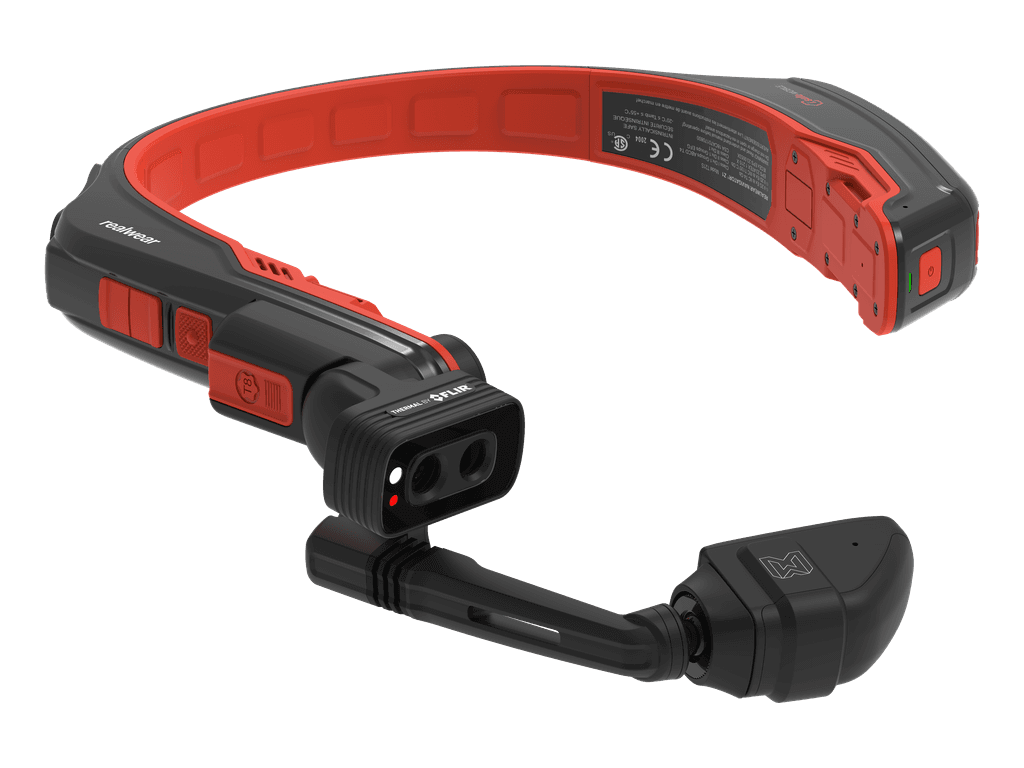

Navigator® Z1 with Thermal Camera

RealWear

Navigator® 520

Designed for all day comfort, enjoy a sharper and bolder view and thermal camera.